Aging Booker's Bourbon: Finding the 'Sweet Spot' for Flavor

When it comes to aging bourbon, Booker’s small batch bourbon has the process literally down to a science. Currently produced by the Jim Beam distillery, it was Jim Beam’s grandson, Booker Noe, who founded this brand in 1992 with bourbon from barrels he personally selected.

According to the Booker’s Bourbon website, Booker was actually raised at a Kentucky distillery and brought his family’s six generations of master distillery knowledge to his bourbon batches.

How does Booker’s perfectly age their bourbon?

As we pretty much all know, bourbon ages in wooden barrels. When the weather becomes hot and humid, like it does during those sticky Kentucky summers, the wood expands and absorbs the bourbon, allowing for a chemical interaction between the bourbon and the wood. In colder weather, the wood contracts and the bourbon escapes the barrel’s walls. This interaction changes the spirit’s taste and color. The longer bourbon is in the barrel, the smoother the taste, (up to a certain point, that is).

Barrels are kept in rackhouses where temperatures can easily be regulated. Rackhouses were originally built out of stone with several wooden floors and an exposed dirt basement to control humidity and large temperature swings. The windows were designed to keep the buildings well-ventilated.

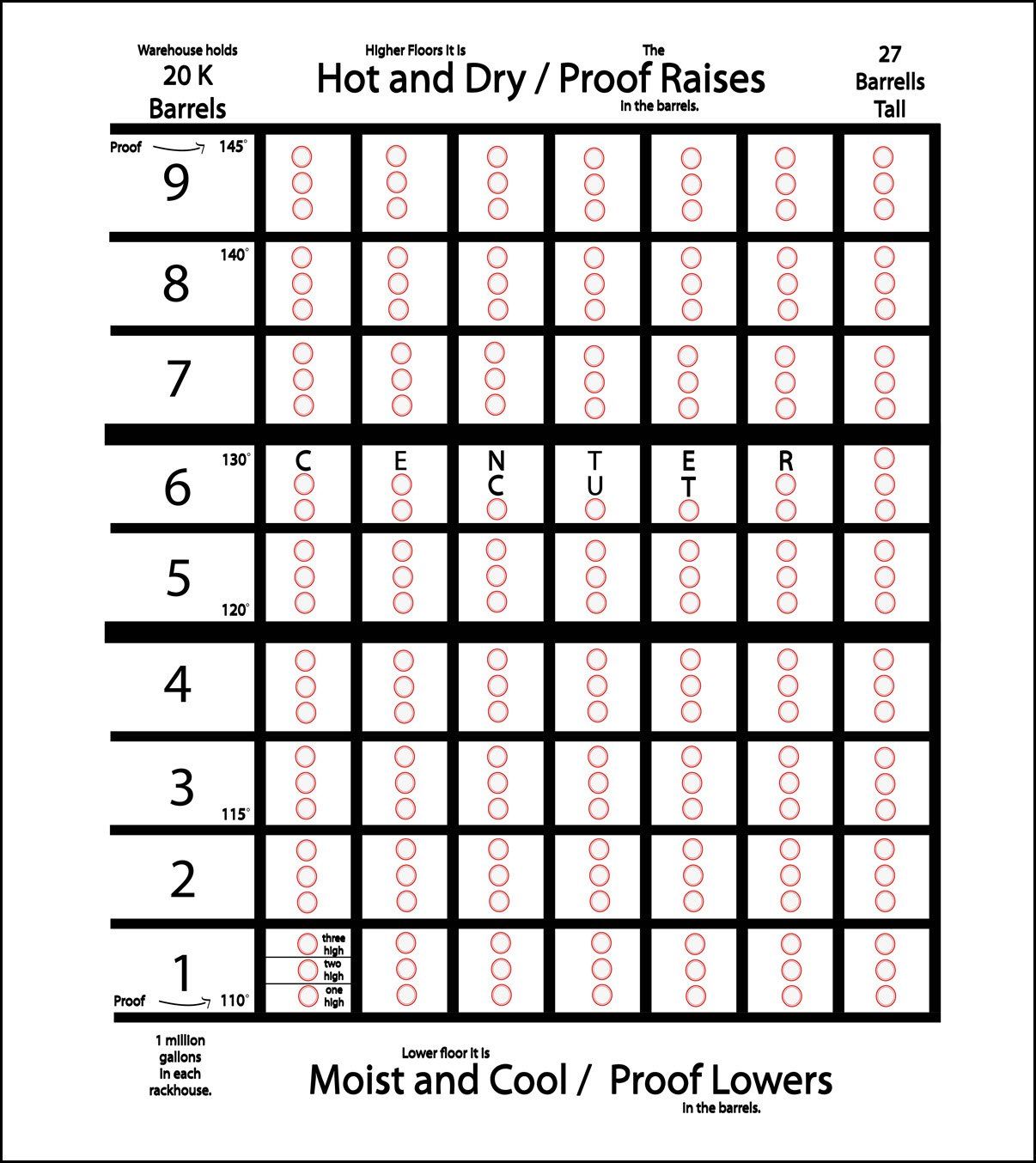

In the above diagram of a traditional nine-story rackhouse (which holds 20,000 barrels/1 million gallons of bourbon!), you can see how the barrels are arranged. Higher floors are hotter and dryer. Because water molecules are smaller than alcohol molecules, the water molecules escape the barrels at a much faster rate and the proof of the alcohol increases. On the lower floors, where it’s moist and cool, water molecules from the air enter the barrels and the proof decreases.

Booker’s Bourbon is aged in barrels in the middle of the rackhouse versus the outside where bourbon is exposed to more heat and ages more quickly. As mentioned on their website, the middle of the rackhouse is the “sweet spot.” It’s “where the temperature and humidity stars align to create the deepest and most intense flavors.”

Newer construction rackhouses are being created that are more cost-effective to build. However, they don’t have as much control over the interior temperature of the building, and the bourbon barrels must be rotated while aging in order to compensate.

There are even rackhouses being built to purposely allow sharp temperature shifts in order to accelerate the aging process. However, according to true bourbon connoisseurs, this bourbon doesn’t quite make the cut.

Looking for a bourbon taste-test to go along

with your new barrel-aging expertise? If you’re in the Irving, TX area, check

out Front Burner’s

new location of their restaurant Whiskey Cake. The restaurant not only features the largest whiskey selection

in the Dallas-Fort Worth area, but also our white oak tables made out of

reclaimed wood from an actual 1920s Booker’s bourbon distillery (see images below).

And if you’d like to infuse a sense of history

into your next design project, contact us here.